Laurie Fox

Guest

|

Posted: Tue Jan 17, 2012 9:34 pm Post subject: GripTru chuck (picture) Posted: Tue Jan 17, 2012 9:34 pm Post subject: GripTru chuck (picture) |

|

|

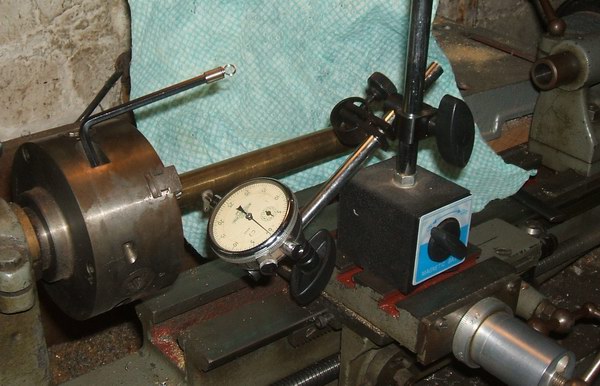

The GripTru chuck is similar to a normal 3 jaw chuck but differs in one important respect. The internal scroll which moves the jaws is positioned inside the chuck body by three conical wedges which can be moved in and out by rotating with an allen key. By adjusting these wedges the centre line of work held in the chuck can be made to coincide closely with the centre line of the headstock. They can be set to differ by less than 0.0002" fairly easily. Very useful on occasions when second operations need an item to be put back into the chuck again.

Laurie |

|

Christopher Carnley

Joined: 16 Nov 2007

Posts: 2749

Location: Yorkshire, United Kingdom

|

Posted: Wed Jan 18, 2012 9:58 am Post subject: Posted: Wed Jan 18, 2012 9:58 am Post subject: |

|

|

Laurie,

Interesting, and I like your oilers.

Last year a young female apprentice was dragged in to a lathe by her long hair, flying in the face of all instruction. She died after exsanguination, CSI speak for blood draining.

That open headstock scares me.

Chris. |

|

bartonmd

Joined: 21 May 2021

Posts: 6

Location: California, USA

|

Posted: Mon Jun 07, 2021 2:44 am Post subject: Set tru chuck Posted: Mon Jun 07, 2021 2:44 am Post subject: Set tru chuck |

|

|

I'm a new member browsing this forum. I realize that I reply to an old post which may no longer be of interest. But I trust that this is no transgression.

You show a really interesting chuck. The sliding wedges seem a very clever way of centering. I have a Pratt-Bernard chuck about two years old. Like several others on the American market uses 4 grub screws to mount the scroll plate and jaws. It is dialed in like the work in a four-jaw chuck. 0.0002" is tir is readily attained. With care it is as good as a Collett.

Anyone still reading doubtless realizes that I'm an American. I live in a small town fairly near Sacramento. Being new to the conventions of the club and a speaker of a foreign dialect, I am curious as to whether this context defines a special meaning to "I like your oilers" said by a Gentleman to a Lady. Any help with cultural orientation is appreciated.

Finally, applicable to the lathe forum, is my considerable curiosity about single-point creation of classic English threads. It's easy enough to grind a 55 degree point on a tool. But how does one deal with the radii at crest and valley? It would appear that a different tool is required for each thread pitch. I will spare you my various guesses. But I thank you for any light you can shed. |

|

Dan Suskin

Joined: 22 Feb 2011

Posts: 298

Location: Georgia, USA

|

Posted: Mon Jun 07, 2021 4:36 am Post subject: Posted: Mon Jun 07, 2021 4:36 am Post subject: |

|

|

| Yo can bring a 55 point trading tool, but it is a lot easier to buy one - especially if you use insert tooling. They are readily available in the US. |

|

bartonmd

Joined: 21 May 2021

Posts: 6

Location: California, USA

|

Posted: Mon Jun 07, 2021 3:32 pm Post subject: Thread cutting tools Posted: Mon Jun 07, 2021 3:32 pm Post subject: Thread cutting tools |

|

|

Thanks for the reply. I have briefly looked at the inserts. My impression was that you need a different insert for each thread pitch. The thought in my mind was that it would be nice to be equipped to cut most any thread I want as I'm accustomed to with 60 degree threads. The impression of a sobering investment quickly formed in my mind.

Just having bought my Bentley (a mk vi), that kind of an investment in tooling will have to wait. I had never imagined that a different thread specification would create a different world. |

|

Dan Suskin

Joined: 22 Feb 2011

Posts: 298

Location: Georgia, USA

|

Posted: Mon Jun 07, 2021 7:18 pm Post subject: Posted: Mon Jun 07, 2021 7:18 pm Post subject: |

|

|

No - you can buy a single point threading insert that will handle any pitch.

Can also do it on a mill using a 55 degree threadmill. |

|

bartonmd

Joined: 21 May 2021

Posts: 6

Location: California, USA

|

Posted: Tue Jun 08, 2021 4:23 am Post subject: Posted: Tue Jun 08, 2021 4:23 am Post subject: |

|

|

| Thanks. That is good to hear. I guess I'm so curious about threads because get confidence from believing that "if I can't find the part I can always cobble it up." How often has being able to cut a thread helped you with your Bentley? Assuming, of course that it is old enough to have Olde English fasteners. I haven't put a hand, much less a wrench on mine. I'm still awaiting delivery from back east. |

|