Robert Lance Hughes

Joined: 08 Jul 2024

Posts: 2

Location: Powys, United Kingdom

|

Posted: Mon Jul 30, 2018 8:21 pm Post subject: 3 litre crack in sump around oil drain plug Posted: Mon Jul 30, 2018 8:21 pm Post subject: 3 litre crack in sump around oil drain plug |

|

|

Today, I have just completed a repair to the sump around the oil drain plug on the 3 litre, and I thought I should take a few minutes to share my experience.

The crack had clearly been caused by overtightening of the sump plug at some point in the cars history. At some point, it had been bodged with a die grinder and some chemical metal, but as soon as the sump plug was removed and retightened, the crack opened and the oil made a nasty mess all over the garage floor.

After speaking to Jimmy Metcalf, he suggested a very elegant solution of fitting a constraining ring around the sump boss to prevent the crack opening up and ensure a long term repair. This is my slightly more rustic version of his repair, but effective nonetheless...

I rummaged around in my workshop and managed to russle up a few pipe fittings to make up a mandrel. A 3/4" BSP to 3/8" BSP reducing bush, and a 3/8" BSP airline fitting, which I drilled out to 1/4". I then used a holesaw to cut a neat face around the sump plug boss.

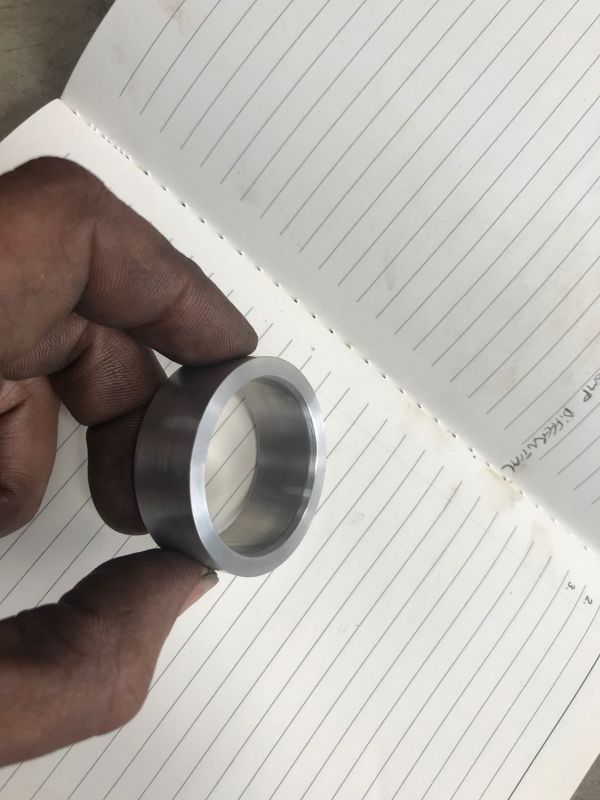

I then accurately measured the diemsions of the newly cut face around the sump plug boss, and machined up an aluminium ring on the lathe with an internal diameter 0.003" smaller...

I put a slight taper on the back of the constraining ring to ensure a good fit...

I then heated the ring up to 160 degrees so it expanded and slipped it onto the boss. This has to be done quickly! It cools very fast once in contact with the sump, and in less than a second was very firmly attached, and pulled the crack tightly closed as it cooled.

I then finished off the job with new magnetic sump plug and copper washer. So far, no leaks from the sump! Although plenty of other leaks from everywhere else! |

|

John Murch

Joined: 05 Jun 1976

Posts: 1577

Location: London, United Kingdom

|

Posted: Tue Jul 31, 2018 5:20 am Post subject: Posted: Tue Jul 31, 2018 5:20 am Post subject: |

|

|

| Brilliant! I wish I had your skills🙂 |

|

Chris Card

Guest

|

Posted: Tue Jul 31, 2018 8:59 am Post subject: Posted: Tue Jul 31, 2018 8:59 am Post subject: |

|

|

I agee with John - brilliant!

Chris |

|

Dan Suskin

Joined: 22 Feb 2011

Posts: 298

Location: Georgia, USA

|

Posted: Tue Jul 31, 2018 1:03 pm Post subject: Posted: Tue Jul 31, 2018 1:03 pm Post subject: |

|

|

| Well done - a great solution, well executed |

|

Christopher Carnley

Joined: 16 Nov 2007

Posts: 2749

Location: Yorkshire, United Kingdom

|

Posted: Tue Jul 31, 2018 2:55 pm Post subject: Posted: Tue Jul 31, 2018 2:55 pm Post subject: |

|

|

I like the shell borer, it reminds me of reaming,tapping and counterboring the sump return boss for the MK VI oil filter conversion,Scheme "B".

Fred Dibnah would have been delighted.  |

|

Robert Craven

Joined: 09 Apr 2004

Posts: 556

Location: Swansea, United Kingdom

|

Posted: Wed Aug 01, 2018 9:33 am Post subject: Posted: Wed Aug 01, 2018 9:33 am Post subject: |

|

|

Very well done.

As I scrolled slowly through and studied your photos one by one I was rather puzzled at what you were aiming at until all was revealed by photo no. 5. |

|