Al Coutts

Joined: 25 Sep 2016

Posts: 108

Location: Norfolk, United Kingdom

|

Posted: Wed Jan 18, 2017 8:49 pm Post subject: Front hub pullers Posted: Wed Jan 18, 2017 8:49 pm Post subject: Front hub pullers |

|

|

| Has anyone designed a nifty little puller that works for Mk VI hubs? I thought I'd ask before I reinvent something already proven. |

|

Stephen Blakey

Joined: 02 Feb 1995

Posts: 1339

Location: Derbyshire, United Kingdom

|

Posted: Wed Jan 18, 2017 9:28 pm Post subject: Posted: Wed Jan 18, 2017 9:28 pm Post subject: |

|

|

Hi Al,

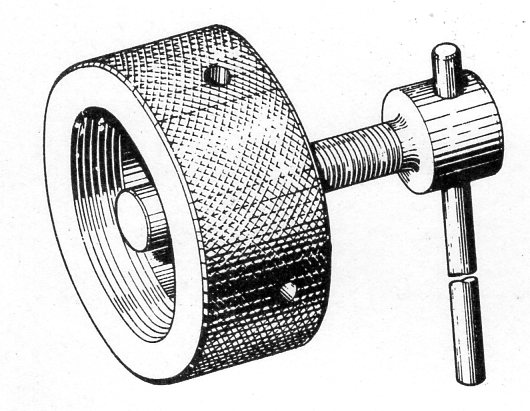

If it won't come off by the application of expletives, you need a 3752/T1005 Extractor, road wheel hub;

If you can't find a 3752/T1005, you could try welding an M20 nut to the centre of the hub cap nut thingy, and maybe some stiffening ribs 'n all, then use a piece of studding to make an approximation of the correct puller?

I'm sure other ideas will be forthcoming. |

|

Al Coutts

Joined: 25 Sep 2016

Posts: 108

Location: Norfolk, United Kingdom

|

Posted: Sun Jan 22, 2017 1:04 pm Post subject: Thanks all Posted: Sun Jan 22, 2017 1:04 pm Post subject: Thanks all |

|

|

I did make up an extractor but it was struggling - the adjuster had been wound up tight and was siezed on.

I ended up extending the legs on a 3 leg puller and it made easy work of it.

|

|

Christopher Carnley

Joined: 16 Nov 2007

Posts: 2749

Location: Yorkshire, United Kingdom

|

Posted: Sun Jan 22, 2017 2:12 pm Post subject: Posted: Sun Jan 22, 2017 2:12 pm Post subject: |

|

|

I put a note on another of your posts,and be careful not to snap the ribs off.

You will find that the bearings for the front hubs on pre- GT chassis are Imperial ball races. |

|

Stephen Blakey

Joined: 02 Feb 1995

Posts: 1339

Location: Derbyshire, United Kingdom

|

Posted: Sun Jan 22, 2017 4:41 pm Post subject: Posted: Sun Jan 22, 2017 4:41 pm Post subject: |

|

|

Hi Al,

Well done and thanks for posting. had I known the drum was stuck fast, I wouldn't have suggested the factory style puller. That's just to get the bearings to slide along the stub axle and they're not a tight fit usually.

If it's not too late, you need to be extremely cautious when removing the brake expander (slave cylinder) and adjuster. Crewe fasteners are made of strong steel and are heavily cadmium plated when new so we get used to them coming apart. The brake equipment was bought in from Girling and neither of the above apply. Those early front cylinders are expensive and difficult to get so are worth preserving. I have had success removing the nuts from the rear expanders by getting the nut and stud cherry red. You might think this would melt the aluminium casting but I think the heat must wick away so quickly into the aluminium, that doesn't happen. In one case, on a very cold day i didn't quite get the thing hot enough and the stud just snapped like a carrot with very little force. The RROC brake overhaul video carries a warning about these studs, as I discovered when I watched it shortly after I'd written off my expander. I got a replacement pair from one of the breakers in the states.

Good luck |

|

Al Coutts

Joined: 25 Sep 2016

Posts: 108

Location: Norfolk, United Kingdom

|

Posted: Sun Jan 22, 2017 7:17 pm Post subject: Posted: Sun Jan 22, 2017 7:17 pm Post subject: |

|

|

All points noted - thank you. I only wound a moderate force onto the puller then using a copper faced hammer - tapped the wheel studs evenly. It took about 15 mins - copious WD40, too! So no damage done.

I'm probably going to regret saying this but so far every nut and bolt regardless of apparent corrosion has actually been quite amenable to moderate force and as soon as the clamping/compression force is removed, most spin out easily!

I'm not used to using half inch drive sockets - so am even more gentle than probably required.

One backplate had no slave cylinder - the other fell out as there was corrosion and it needs lots of TLC or replacing.

|

|